What are the effects of storage conditions on the accuracy and quality of cross roller bearings?

- 2025-03-06

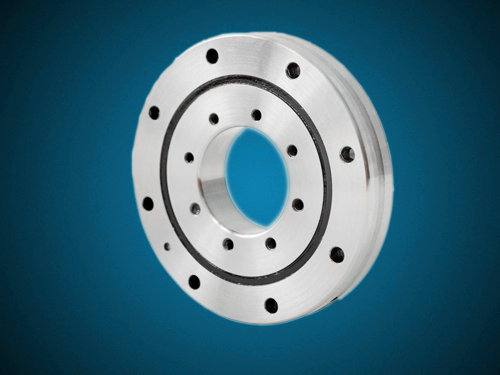

Cross roller bearing is another type of bearing with inner ring division and outer ring rotation. Due to the fact that the divided inner or outer rings are fixed together with the cross roller collar after installing the rollers and spacers, they are separated from each other, making the installation of the cross roller collar simple. Due to the cross arrangement of rollers, only one set of cross roller collars is needed to withstand loads in all directions, which increases the rigidity by 3-4 times compared to traditional models. Meanwhile, due to the fact that the inner or outer ring of the cross roller bearing is a two-part structure, the bearing clearance can be adjusted, allowing for high-precision rotational motion even when preloaded. Moreover, due to its other structures, it is commonly used as joint bearings in industrial robots.

In cross roller bearings, because the cylindrical rollers are arranged perpendicular to each other through spacers, one cross roller bearing can withstand loads in radial, axial, and torque directions. The size of the inner and outer rings has been minimized to a near small size and has high rigidity, making it suitable for joint or rotating parts of industrial robots, rotating workbenches of machining centers, rotating parts of robotic arms, precision rotating workbenches, medical machines, measuring instruments, etc The use of IC manufacturing equipment, etc.

Cross roller bearings, due to the segmented inner or outer ring, are fixed together with the cross roller collar after installing the rollers and spacers, so that they can be separated from each other. Therefore, the installation of the cross roller collar is simple to operate. Due to the cross arrangement of rollers, only one set of cross roller collars is needed to withstand loads in all directions, which increases the rigidity by 3-4 times compared to traditional models. Meanwhile, due to the fact that the inner or outer ring of the cross roller bearing is a two-part structure, the bearing clearance can be adjusted, allowing for high-precision rotational motion even when preloaded.

Cross roller bearings are precision bearings with other structures. Caution is also required when storing it. The accuracy and quality of cross roller bearings can only be maintained in a suitable environment.

1、 Cross roller bearings should be stored in a clean and dry environment, and temperature and humidity should be controlled during handling and storage. The temperature and humidity should be within an acceptable fixed range and should be at least 30cm away from the ground.

2、 Some bearings have a shelf life. For example, bearings with dust covers and oil seals will have a larger starting torque than new bearings after storage for a period of time. At the same time, the lubrication performance of the grease will be damaged after long-term storage, so the bearings should be regularly inspected and maintained on the turntable.

3、 To ensure the normal operation of the bearing, lubrication should be applied to ensure direct metal contact between the rolling elements, raceways, and retainers, which can cause wear and corrosion of the bearing surface. Therefore, in various applications, it is extremely important to choose the appropriate lubricant and lubrication method, while also requiring proper maintenance.

4、 The actual selection of lubricants is mainly based on operating conditions, namely temperature range and speed, as well as the influence of the surrounding environment. If lubrication is possible, the amount of lubricant used for the bearing is small, and its operating temperature is low. However, when it also serves other purposes such as sealing or heat dissipation, the amount used needs to be increased. Therefore, when installing bearings, filling lubricating grease generally fills the remaining space of the bearing, controlling 1/3-1/2 of the remaining space of the bearing box, as too much can easily generate high temperatures.

- Previous

Why does tapered roller bearing produce noise during use?

-

NONE